Product Description:

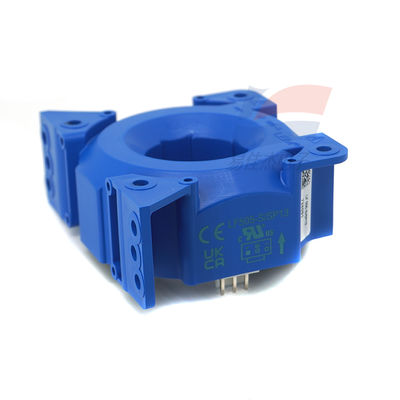

LF1005-S/SP16 Closed-loop Hall Current Sensor Current Transformer

Features:

Drive main applications

The current sensor is used to measure the constantly changing current and feed it back to the control unit for control. This enables adjustments to the operation of the equipment. For a machine tool, the current changes rapidly after the processing of the product begins. The more accurate and timely the feedback signal is, the smoother the operation of the machine tool will be.

Typical applications of drive-type sensors include:

· Elevators

· Escalator

· Household appliances

· Crane

· Wheelchair

· Excavator

Electric access control system

· Robot

· Pump

· Steel mill

· Machine tools (printing, textile, plastic)…

Application of Renewable Energy

More intelligent and effective application of renewable energy

The effective application of renewable energy cannot be achieved without the use of power electronics technology. Modern systems require power semiconductors, control systems, mechanical components, and feedback sensors to work in coordination. Current sensors provide information on the load side to achieve these functions.

Typical applications of new energy include:

· Solar energy

· Wind farm

· Water and Electricity

· Fuel cell

Geothermal power generation

· Tidal energy

Main applications of power supply

Current sensors are crucial for an operational power grid

Stability

In many applications, the grid voltage is too high, or it needs to be converted into direct current or alternating current of different frequencies. Therefore, the grid voltage is converted through power electronic devices. The sensor measures the output current to ensure stable power supply.

Continuity

Power supply is crucial for the normal operation of many applications. For instance, mobile phone base stations and hospital systems always maintain availability. In the event of system failures (short circuit faults, grounding faults, etc.) or power outages in the grid, batteries or UPS systems will provide emergency power. Sensors can be used to control the charging and discharging of batteries as well as the switching between batteries and UPS systems.

The typical applications of power supply include:

· UPS: Uninterruptible Power Supply System

· SMPS: Switching Power Supply

· Communication power supply

· Airport lighting power supply

· Lighting power control

· Battery charger

Trackside main applications

Trackside applications:

In order to reduce the disruptions in train services caused by equipment failures and to lower the costs during the lifecycle, it is crucial to conduct preventive maintenance on key train equipment (such as turnouts, platform screens, signaling systems, rails, etc.). Online monitoring can enable the necessary preventive actions to be taken before abnormal conditions leading to failures occur.

For instance, the motor current of the switch machine can be monitored through sensors. If the current deviates from the normal value, it indicates that there might be a device malfunction, and preventive maintenance is required. A prompt maintenance can prevent the interruption of train operation and thus save a significant amount of costs.

Typical applications at the roadside:

· Orbit target monitoring

· Switch machine

· Track Circuit

· Escalator doors

Substation (circuit breaker of the transformer...)

· Control and System

Main applications of automation

Improving the efficiency of process automation

Traditional process control requires monitoring and adjusting parameters such as temperature, pressure, torque, and position. However, directly measuring these parameters is not only inefficient but also inaccurate. Measuring the input current of the load can provide more information beyond the current value, and it has many other advantages such as speed, ease of use, reliability, cost savings, etc. More and more process automation and condition monitoring applications are following this trend.

Installing an electricity sensor on the control panel or motor drive can achieve the following functions:

Monitor the status of various electrical mechanical components

Adjust various parameters

· Fault Warning

· Backup system starts up

Typical applications of process automation include

· Machinery and panel manufacturers

System integrator / engineering contractor

· Production and Personal Protection

· Process Control: Supervision and Automation (Furnace, Electrolysis Process, Electrical and Mechanical Installation Monitoring)

· Maintenance Activity: Condition Monitoring

· Facilities and infrastructure management (such as cathodic protection current, driving force for transporting materials, etc.)

· Electricity production and consumption (on-site electricity metering for individual consumption)

Specifications:

| Power supply |

±15 to 24V - 40 to 85°C |

| Current |

1000A |

| Packaging |

Boxed |

| Accuracy |

0.75% |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!